Knife Sharpening

Knife sharpening is the process of making a knife or similar tool sharp by grinding against a hard, rough surface, typically a stone, or a flexible surface with hard particles, such as sandpaper.

The smaller the angle between the blade and stone, the sharper the knife will be. The angle between the blade and the stone is the edge angle – the angle from the vertical to one of the knife edges, and equals the angle at which the blade is held. The total angle from one side to the other is called the included angle – on a symmetric double-ground edge (a wedge shape), the angle from one edge to the other is thus twice the edge angle. Typical edge angles are about 20° (making the included angle 40° on a double-ground edge). The edge angle for very sharp knives (like wood carving knives) can be as little as 10o (for a 20° included angle). Knives that require a tough edge (such as those that chop) may sharpen at 25° or more.

Different knives are sharpened differently according to grind (edge geometry) and application. For example, surgical scalpels are extremely sharp but fragile, and are generally disposed of, rather than sharpened, after use. Straight razors used for shaving must cut with minimal pressure, and thus must be very sharp with a small angle and often a hollow grind. Typically these are stropped daily or more often. Wood carving knives are generally stropped before each use, and as periodically during use. At the other extreme, an axe for chopping wood will be less sharp, and is primarily used to split wood by chopping, not by cutting or slicing, and may be reground but will not be sharpened daily. In general, but not always, the harder the wood to be cut, the higher (duller) the angle of the edge.

Knife sharpening proceeds in several stages, in order from coarsest (most aggressive) to finest (least aggressive). The stages are:

- sharpening: removing metal to form a new edge

- rough sharpening (using either water stones, oil stones, or medium grits of sandpaper as in the scary sharp method of sharpening)

- fine sharpening (using the same tools as above, but in finer grits)

- stropping (also referred to sometimes as polishing) giving a mirror finish, but not significantly altering the edge.

Blade damage

Blades are damaged primarily by “buckling” – compressive force, from being pressed into a hard object, such as a hard piece of wood or a wood knot – and by “bending”, from sideways pressure. Both of these tend to roll the edge of a blade, due to the metal’s ductile nature. Blades may also be damaged by being corroded.

Inspection

Blade sharpness can be checked in multiple ways.

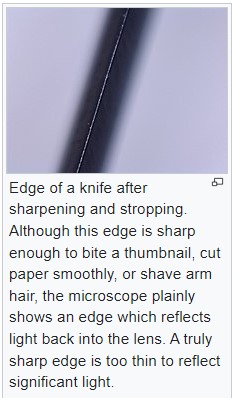

Visually, a very sharp knife has an edge that is too small to see with the naked eye; it may even be hard or impossible to resolve under a microscope. The shape near the edge can be highlighted by rotating the knife and watching changes in reflection. Nicks and rolled edges can also be seen, as the rolled edge provides a reflective surface, while a properly straightened edge will be invisible when viewed head-on.

By touch, a blade can be checked by running a thumb across the blade (perpendicular to the edge – not along, which will cut it). A sharp blade will have a distinct edge, like a corner, and may sing slightly from vibration, while a dull blade will have a round edge and the thumb will slip over it.

A blade’s sharpness may be tested by checking if it “bites” – begins to cut by being drawn across an object without pressure. Specialized sticks exist to check bite, though one can also use a soft ballpoint pen, such as the common white Bic Stic. A thumbnail may be used at the risk of a cut, or the edge of a sheet of paper. Another way to test a wood carving knife’s blade for sharpness is to slice a piece of basswood across the grain. The blade should slide through with minimal pressure and leave a smooth cut without any marks.

Grinding

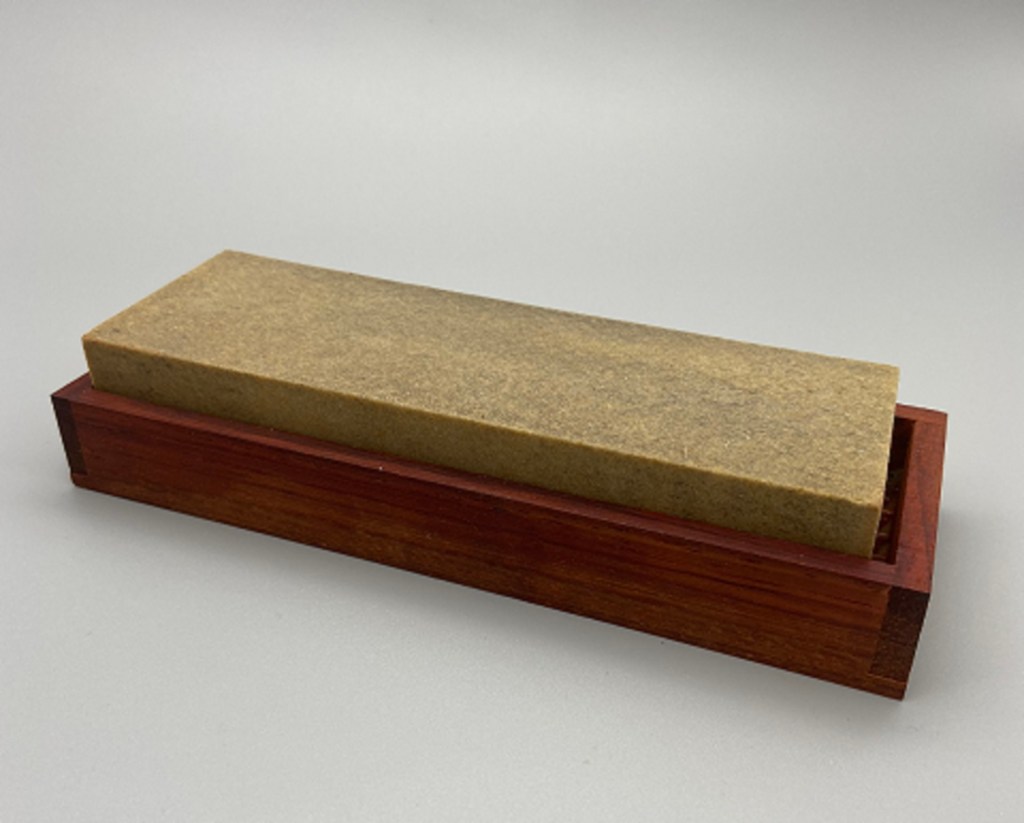

Hand grinding is generally done with a sharpening (honing) stone. Sharpening stones come in coarse and fine grits and can be described as hard or soft, based on whether the grit comes free of the stone with use. Many sources of naturally occurring stone exist around the world; some types known in the ancient world are no longer used due to theexhaustion of former resources or the ready availability of superior alternatives. Arkansas, USA, is one source for honing stones, which are traditionally used with water or honing oil.

India is another traditional source for stones. Ceramic hones are also common, especially for fine grit size. Japanese water stones (both artificial and natural) come in very fine grits. Before use, they are soaked in water, then flushed with water occasionally to expose new stone material to the knife blade. The mixture of water and abraded stone and knife material is known as slurry, which can assist with the polishing of the knife edge and help sharpen the blade. Generally, these are more costly than oilstones. Coated hones, which have an abrasive, sometimes diamonds, on a base of plastic or metal, are also available.

Diamond stones can help sharpen. Diamond is the hardest naturally occurring substance known, and as such can be used to sharpen almost any material. (Coarse diamond sharpening stones can also be used for flattening water stones.

Power grinding is generally done on a powered rotating wheel with either a grinding stone or sandpaper. Most modern day knife makers begin their blade sharpening process with power grinding – mostly because it is much faster than hand grinding. Like in hand grinding, various grits of stones and sandpaper are used in the process of power grinding.

Stropping

Stropping a knife is a finishing step. This is often done with a leather strop, either clean or impregnated with abrasive compounds (e.g., aluminum oxide or diamond paste), but can also be done on paper, cardstock, or cloth. Most modern-day knife makers power-strop their knives on cloth buffing wheels. Stropping removes little or no metal, but produces a very sharp edge by either straightening or very slightly reshaping it. It may bring a somewhat sharp blade to “like new” condition.

Reader’s Comments

My good friend, Gary Baker had a nice comment about my last issue:

“Another enjoyable informative issue, thank you. Gary Baker”

Thank you for your kind words, Gary!

Questions & Answers

I recently got a question from subscriber, Joe Aguilar looking to purchase Bo- T knives and gouges. Joe asks:

Is anyone selling Bo- T knives and gouges? Please let me know at joeaguilar979@gmail.com. or 956-564-0222. thank you. I can’t seem to find anyone who sells them.

Honestly, Joe, I have never heard of them. However, if anyone knows how to obtain Bo- T knives and gouges, please get in touch with Joe.

Photo Shop

“Photo Shop” is the section of Wood Chip Chatter where carvers can send in photos of their wood carvings for display. It’s your chance to show off your work…sort of a show and tell. The photos will only be displayed and no comments or critiques will be made. For critiques on your carvings send them in to the “Carver’s Corner.” Send your photos to: carverbobk@

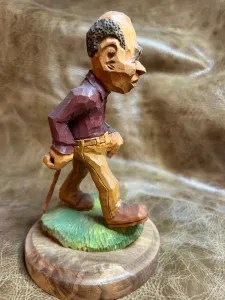

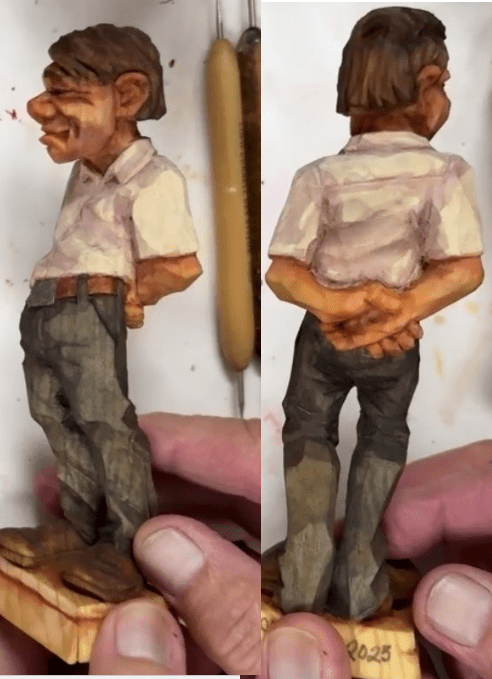

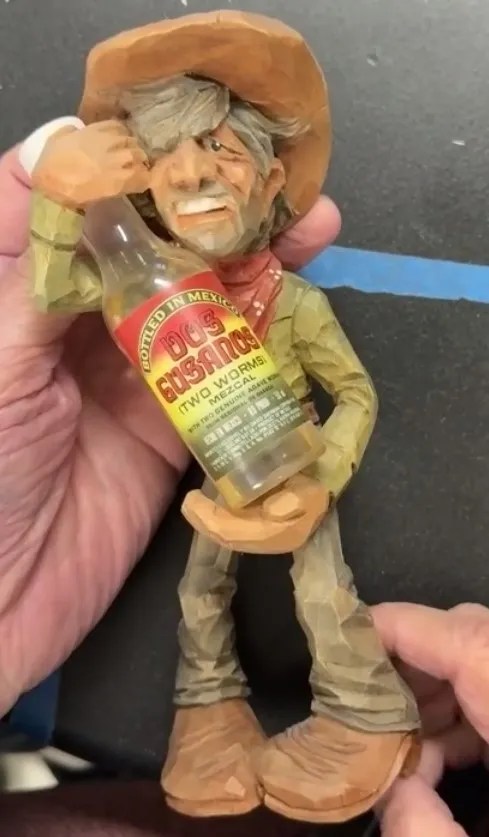

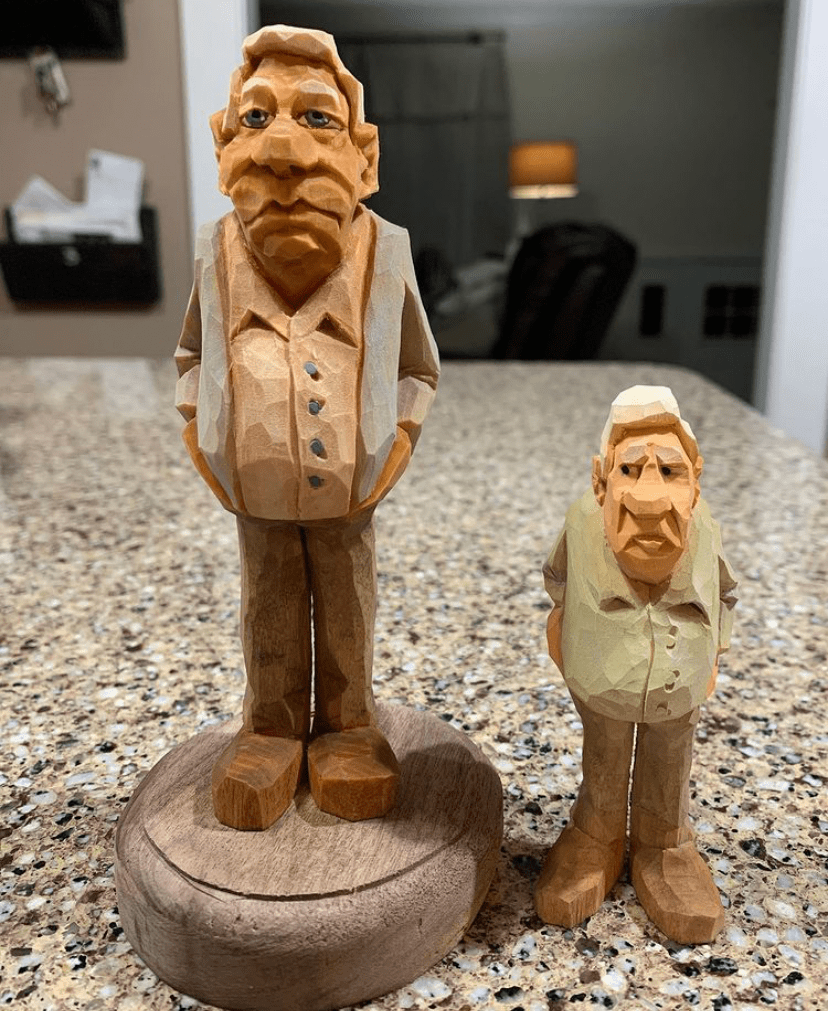

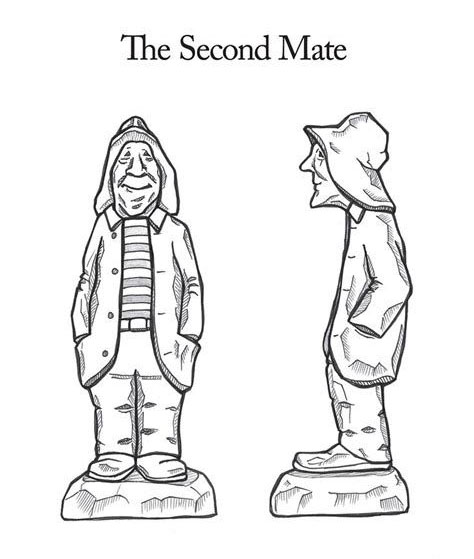

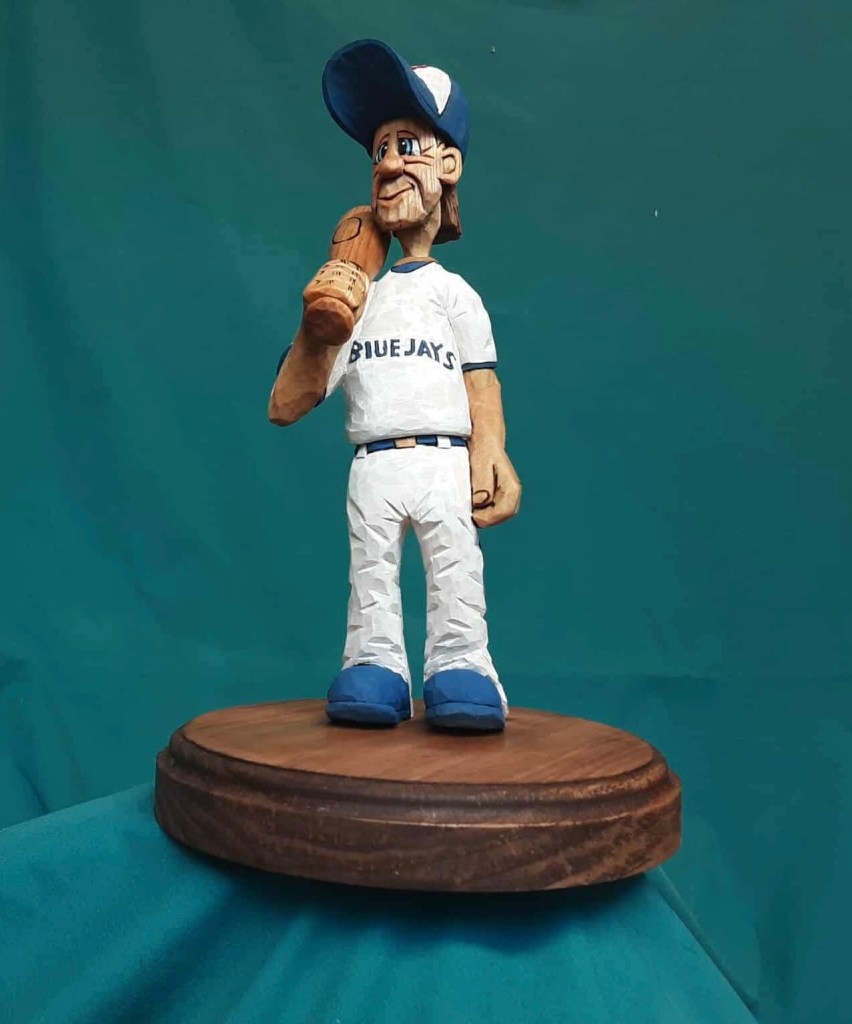

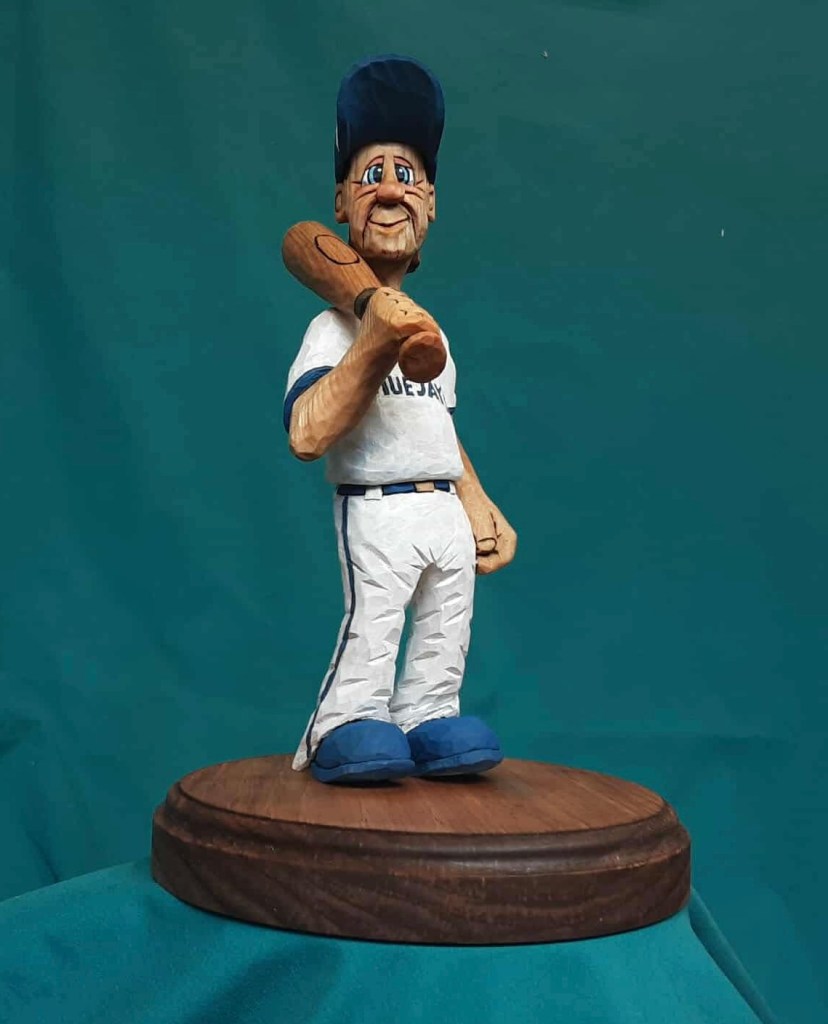

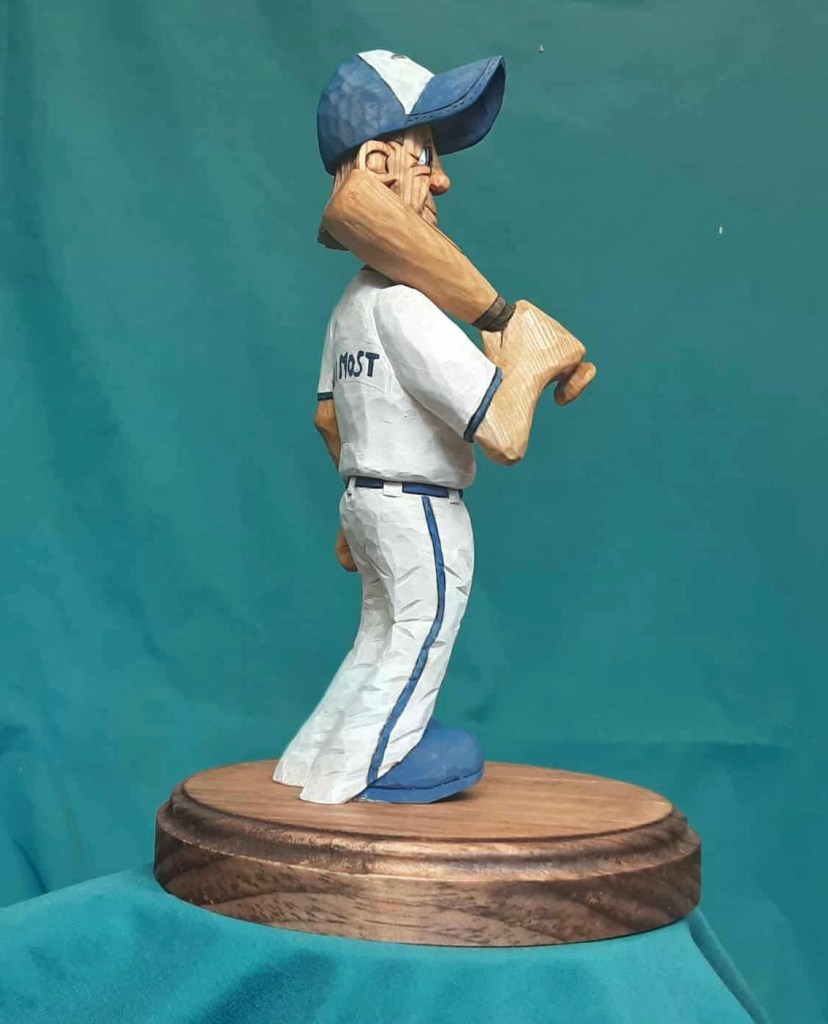

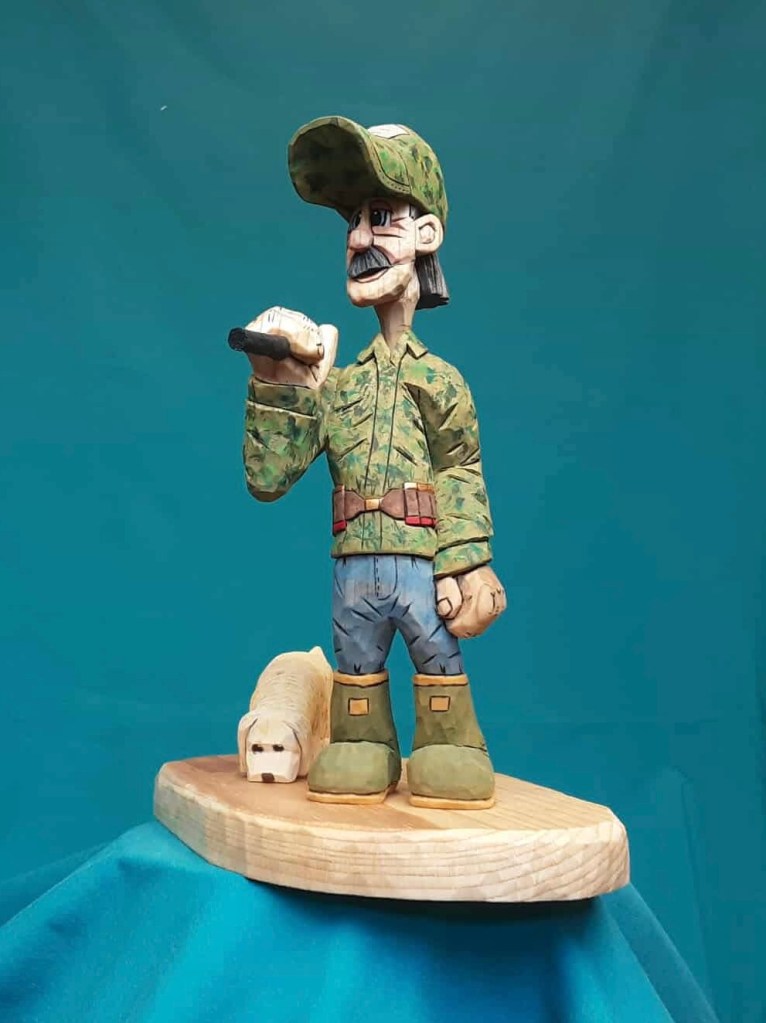

My very good friend, Wayne Smith, from Nova Scotia, Canada sent some photos of a couple of his recent carvings:

Awesome carvings, Wayne! I always love seeing your work! Thank you for the photos!

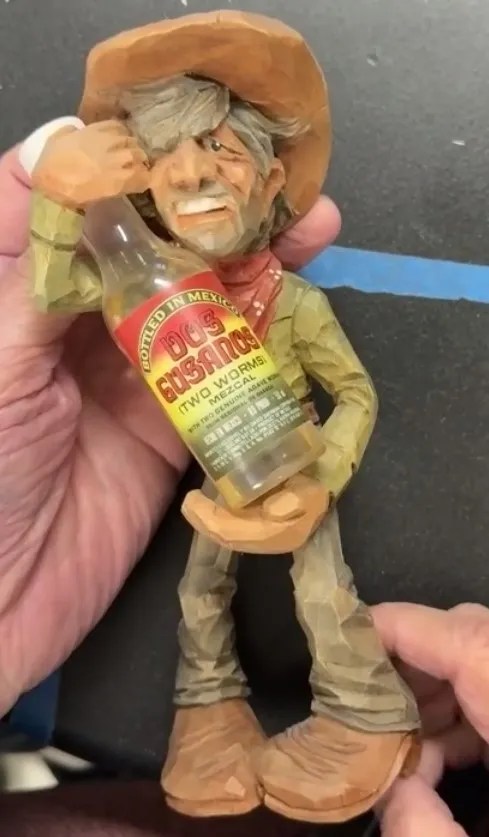

My very good friend, Jim Babcock sent a photo of one of his recent carvings. Jim writes:

“Bob:

Best wishes for the New Year. Attached is a recent carving, finished with

oil based stains.

Jim Babcock

Columbus, Indiana”

Very nicely done, as always, Jim!

Here is another photo from Jim Babcock that just came i last minute. Jim writes:

“Bob:

Hope all is well. attached is an image of another lotus flower; this one finished

with walnut oil and then heavily diluted acrylics.

jim babcock

Columbus, Indiana”

Very clean work, Jim! I like it.

Woodcarving Tip

Keep your knife sharp. Your carving experience will be much more enjoyable when you carve with a sharp knife. When your knife starts to feel dull, strop it. It only takes a minute and your knife will repay you for it.

To be sure my knife is sharp for the next time I carve I always strop it after every time I’m finished carving. Just a few quick strokes on your leather strop is all it takes and your knife is always ready to go.

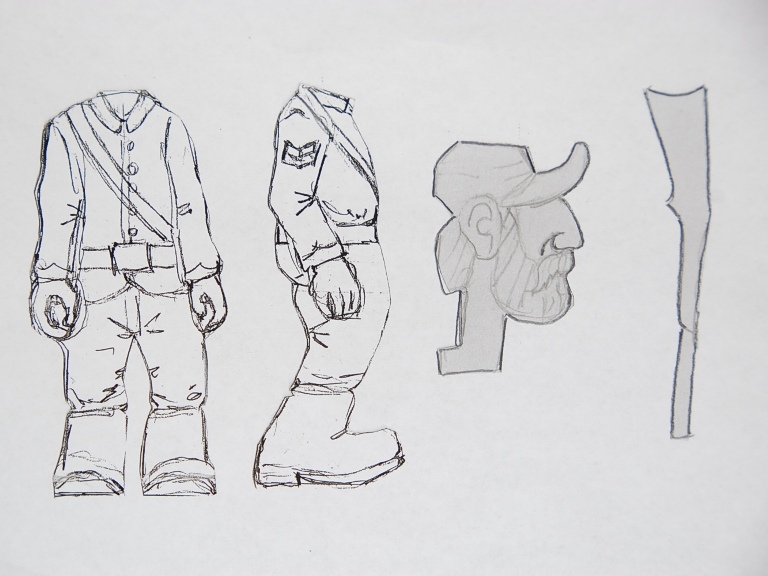

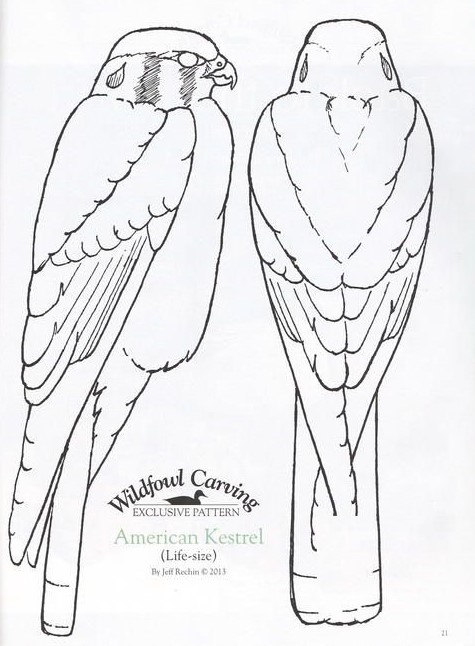

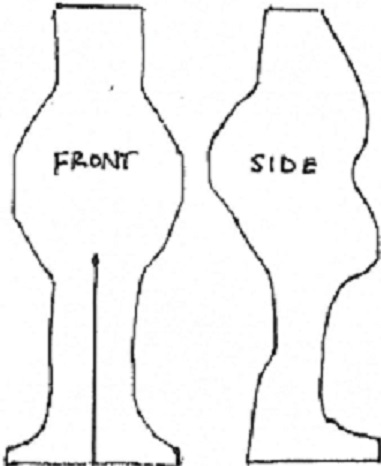

Pattern of the Month

Various Gnomes

Coming Workshops

Cute Gnome

Teacher: Dwayne Gosnell

Dates: Feb 3,17 – 6PM Eastern

Twiitling Tuesday – 4 hours ( 2 sessions – 2 hours each day)

Location: Online (Via Zoom)

For details and to sign up click on Dwayn’s website https://www.dgosnellwoodcarving.com/

Funny Horse

Teacher: Dwayne Gosnell

Dates: March 3,31 – 6PM Eastern

Twiitling Tuesday – 4 hours ( 2 sessions – 2 hours each day)

Location: Online (Via Zoom)

For details and to sign up click on Dwayn’s website https://www.dgosnellwoodcarving.com/

Gnome riding his Turtle

Teacher: Dwayne Gosnell

Dates: April 14,28 – 6PM Eastern

Twiitling Tuesday – 4 hours ( 2 sessions – 2 hours each day)

Location: Online (Via Zoom)

For details and to sign up click on Dwayn’s website https://www.dgosnellwoodcarving.com/

Left-handed Larry

Teacher: Dwayne Gosnell

Dates: May 12,26 – 6PM Eastern

Twiitling Tuesday – 4 hours ( 2 sessions – 2 hours each day)

Location: Online (Via Zoom)

For details and to sign up click on Dwayn’s website https://www.dgosnellwoodcarving.com/

Online Classes With Chris Hammack

Teacher: Chris Hammack

Chris Hammack is offering a new series of online classes to help students learn and sharpen their woodcarving skills. Individual and Group Classes are available through his website, chrishammackart.com/groupclass

Twhitling Tuesdays

Teacher: Dwayne Gosnell

Dates: Two – 2 hour classes each month on Tuesdays

Location: Online (Via Zoom)

To sign up, contact Dwayne Gosnell via email at dagwood_76@gmail.com

Woodcarving Academy

Established in 2020, the Woodcarving Academy offers dozens of videos and seminars created by some of the country’s top level instructors. More videos are added regularly as they are created by the instructors.

With a paid subscription to the Woodcarving Academy you can view any videos you like for as many times as you like.

Subscription rates: Monthly = $19.95 Quarterly = $49.95 Annual = $139.95

There is even a Free level which allows you to tour the website and watch the sample videos and content, and receive email updates as new content becomes available.

Check out the Woodcarving Academy and learn with the masters right in the comfort of your own home! Go to: www.woodcarvingacademy.com or Email: support@woodcarvingacademy.com

News & Announcements

The International Association of Woodcarvers has upcoming Zoom meetings on the following Saturdays at 3PM EST with special guest presenters. Check them out…

Zoom: 310-460-3575

Presentation Schedule:

2/7 – Sara Barraclough

2/28 – John Overby

3/7 – Rod Gatlin

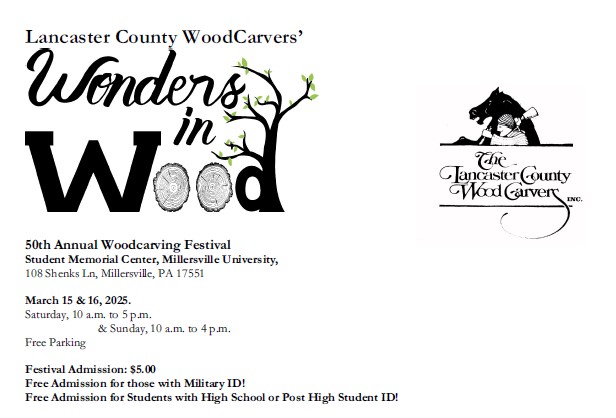

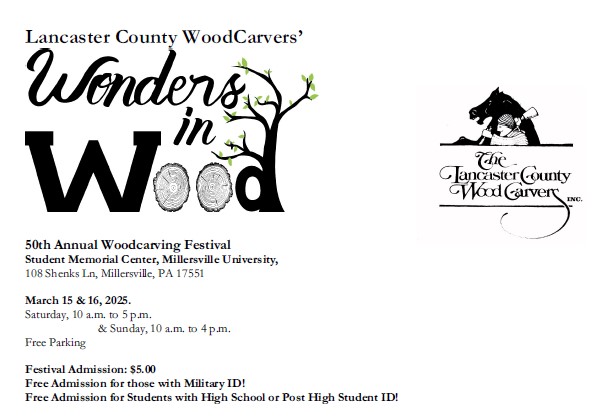

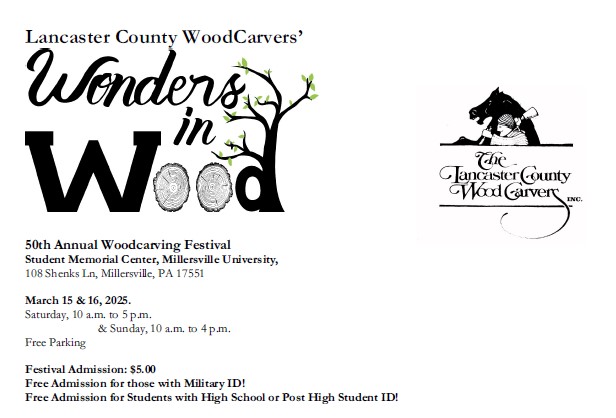

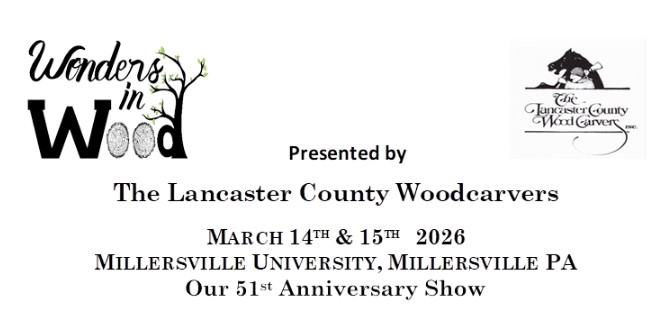

3/14 – Lancaster County Show (Wonders in Wood)

INTERNATIONAL ASSOCIATION OF WOODCARVERS

COME JOIN US!!!

The Jersey Hills Wood Carvers (JHWC) club is a small but growing group of wood carvers sharing their time, knowledge and joy of woodcarving. The JHWC generally meets from 7:00 PM EST to 9:00 PM EST on the 1st, 3rd and 5th Thursday of each month (when school is in session) at the Jefferson Township High School wood shop classroom.

Membership is “FREE” and open to anyone interested in woodcarving regardless of their ability.

JHWC’s Upcoming Meetings and Event

2026

February: 19th

March: 5th, 19th

April: 16th, 30th

May: 14th, 28th

June: 6th

For more information contact:

Al Santucci alsantucci4@gmail.com President

Bill Brunner billbrunnerdesign@gmail.com newsletter/website editor

Or visit:

Website: https://www.jerseyhillswoodcarver.com/ Facebook: https://www.facebook.com/groups/736479646821641/

AML Wood Carving Knives

AML Wood Carving Knives are handmade by Andy Loughlin in Monroe, New York.

Each blade is meticulously crafted from 1095 high-carbon steel, ensuring easy sharpening and long-lasting edge retention. The diverse exotic woods used for the handle styles are sourced from around the world, adding a touch of elegance to these knives. You can find these exceptional knives for auction on eBay under ‘AML Knives,’ with bidding usually starting at $22 and most knives selling for between $40 and $100.

Unpack your AML Wood Carving Knife and experience its razor-sharpness right out of the package. Each knife comes with a custom-made magnetic wooden sheath, a thoughtful addition at no extra cost.

I now own three AML Knives and can speak personally about their quality. These are not production knives. Each knife is handmade by Andy himself. The knives are sturdy, well made, and will stack up to any other knife on the market. These knives have quickly become quite popular and sell out fast, so check the site (“AML Carving Knives” on EBAY) often for availability.

Andy has recently begun making knives with handles made from exotic woods and colored epoxy, creating some stunning and unique handle designs. Below are examples of some knives currently available or which have recently sold:

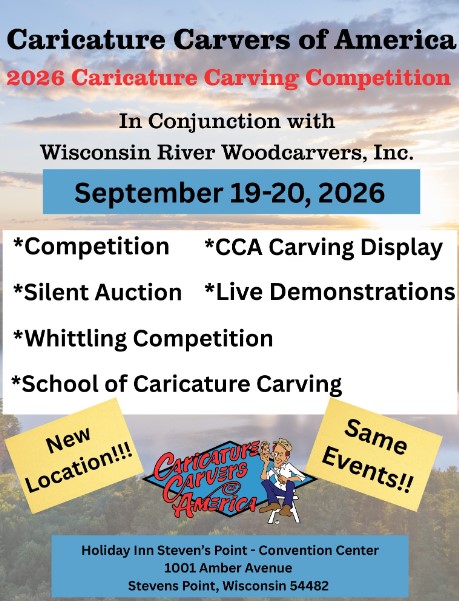

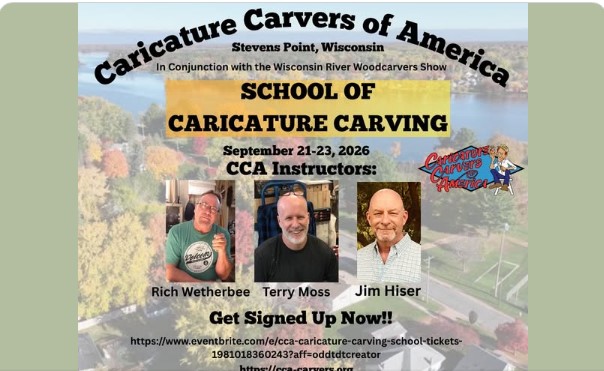

Courtesy Announcement

As the wood carving show schedule begins to kick into gear I want to extend an invitation to anyone who’s carving club is planning a show this year to submit your show information so I can promote it in Wood Chip Chatter. Copies of your show announcement flyers are greatly appreciated. Send to carverbobk@woodchipchatter.com or rwkoz51@gmail.com

Call for Content Contributions!

I am excited to announce an opportunity for you to contribute to the pages of Wood Chip Chatter. I am looking for diverse and engaging content that resonates with our audience and aligns with our mission of wood carving and whittling.

I’m certain you all have some great material to share with our Wood Chip Chatter community. Comments and questions are always welcome, and they make the newsletter more interesting and informative. Of course, photos of your work (new or old) are always appreciated.

You may want to relate a story or experience you’ve had, or write a brief article on a carving-related matter. I’m not fussy, it doesn’t have to be perfect, and I can always doctor it up on my end.

Wood carvers have long been known as a very sharing-type group, so let’s see what everyone has to share through Wood Chip Chatter.

Send all content to: carverbobk@woodchipchatter.com

Thank you, and I look forward to hearing from you!

The next issue of Wood Chip Chatter will be posted on April 3, 2026

Keep a sharp eye out for it!

Keep a sharp edge, and keep on carvin’!

Funny Bone